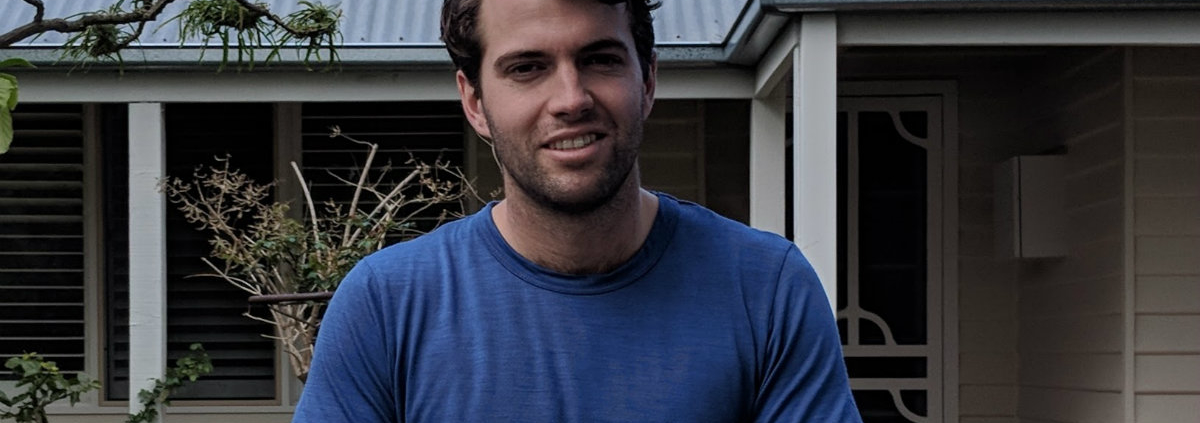

#106 Who is Flock Wool?

In this interview, CEO of Flock Wool, Evan Thomsen, shares the story of how he developed the idea for an Albanian Wool Trading company. You will learn how Evan and his wife Tyanna set out to find the right team, develop the business strategy, and start a new business in Albania trading wool.

Watch the full interview on video below or listen to the audio file with the link above or via your preferred podcast provider.

Background Season 2

After being on a break for around 1,5 years, the Wool Academy Podcast is back with its Season 2 episodes. The focus of the podcast remains the same – learning from wool industry experts and telling the beautiful stories wool has to tell. However, a few things have also changed as well. In January 2020, I joined an Albanian Wool Trading Company called Flock Wool. In many of the season 2 episodes, you will, therefore, be invited to join the Flock Wool journey as we learn how to start and develop a little wool trading company in Albania. You will be hearing discussions between Evan Thomsen and myself as we discuss different aspects of the Flock Wool business. On this journey, I will also speak to other people in the industry trying to set up similar ventures. One more new feature, all interviews are recorded by video, so you can now not only listen on the go as usual but also watch if you feel like it. I hope you enjoy season 2 of the Wool Academy Podcast.

About Flock Wool

Founded in 2019, Flock Wool Trading Company is an international wool export company headquartered in Dalton, Georgia, USA, with an operational HQ in southern Albania. The Flock Wool team is located in Albania, Germany, and the US in order to best serve its customers. All of the company’s wool is 100% sourced from Albania.

How to connect with Evan Thomsen

Website: https://flockwool.com/

Other episodes you may want to check out

Flock Wool

Flock Wool

Nan Bray - White Gum Wool

Nan Bray - White Gum Wool

Visual Narrative

Visual Narrative  Dr. Paul Swan

Dr. Paul Swan Foggy Bottom Boys

Foggy Bottom Boys Kia Ora Australia

Kia Ora Australia Verrena Keller from know your stuff

Verrena Keller from know your stuff

Pam and Andre Christie-Smith

Pam and Andre Christie-Smith Elisabeth van Delden

Elisabeth van Delden

Elisabeth van Delden

Elisabeth van Delden